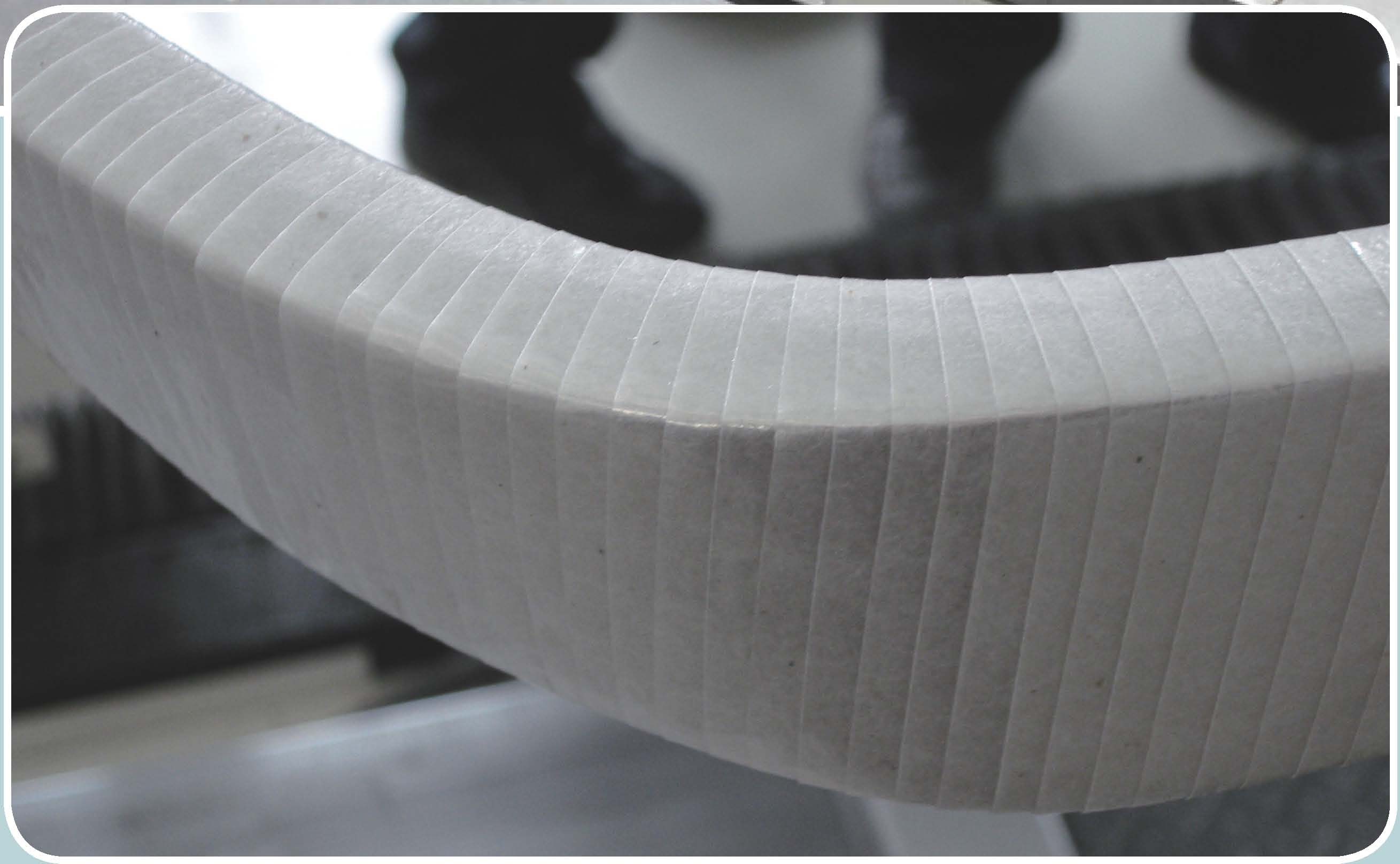

CNC taping machine final product

CNC taping machine for fusiform coil:

Coil section size: (5~20)×(30~60)mm²;

Insulation tape width: 20mm, 25mm;

Tape reel's inner diameter: 25mm, 40mm. outer diameter: 110mm;

Fusiform part length: 350~2300mm (3200mm).

Straight line length: 300~1600mm (2500mm), adjustable steplessly;

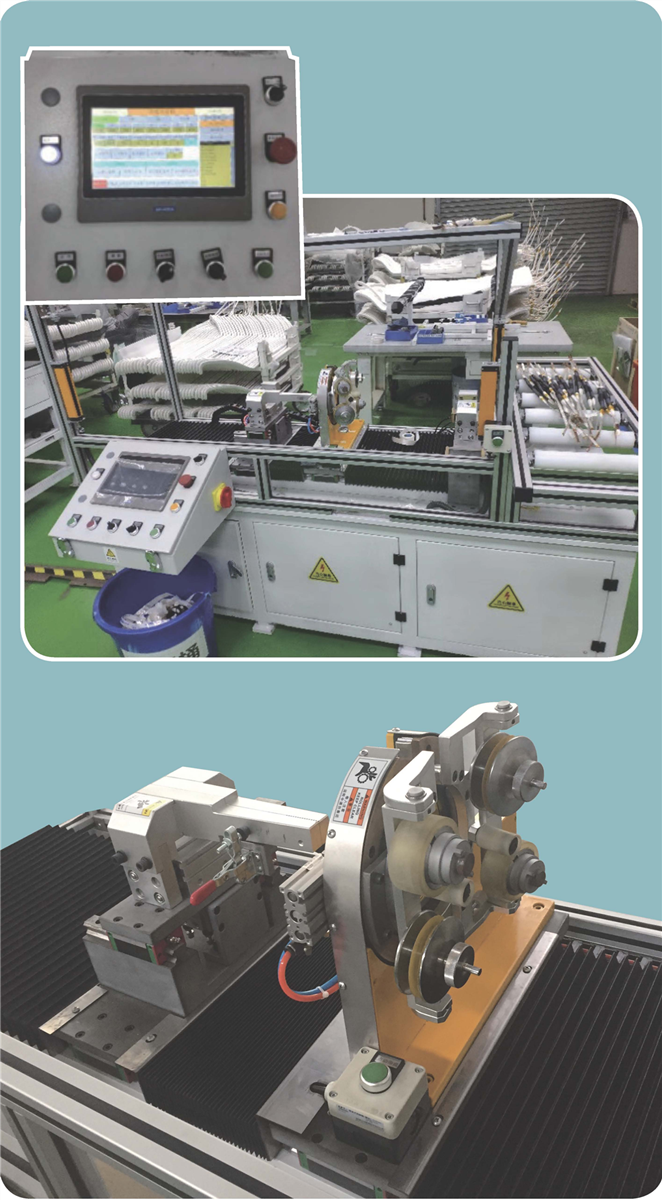

Multi-purpose insulation tape CNC taping machine general for coil

Coil section size: (5~50)×(30~90)mm²;

Insulation tape width: 20mm, 25mm;

Tape reel's inner diameter: 25mm, 40mm. outer diameter: 110mm;

Wire rod length range: 700~(2200)3600mm.

The single-side projection distance between the wire rod's two ends 300mm, adjustable steplessly;

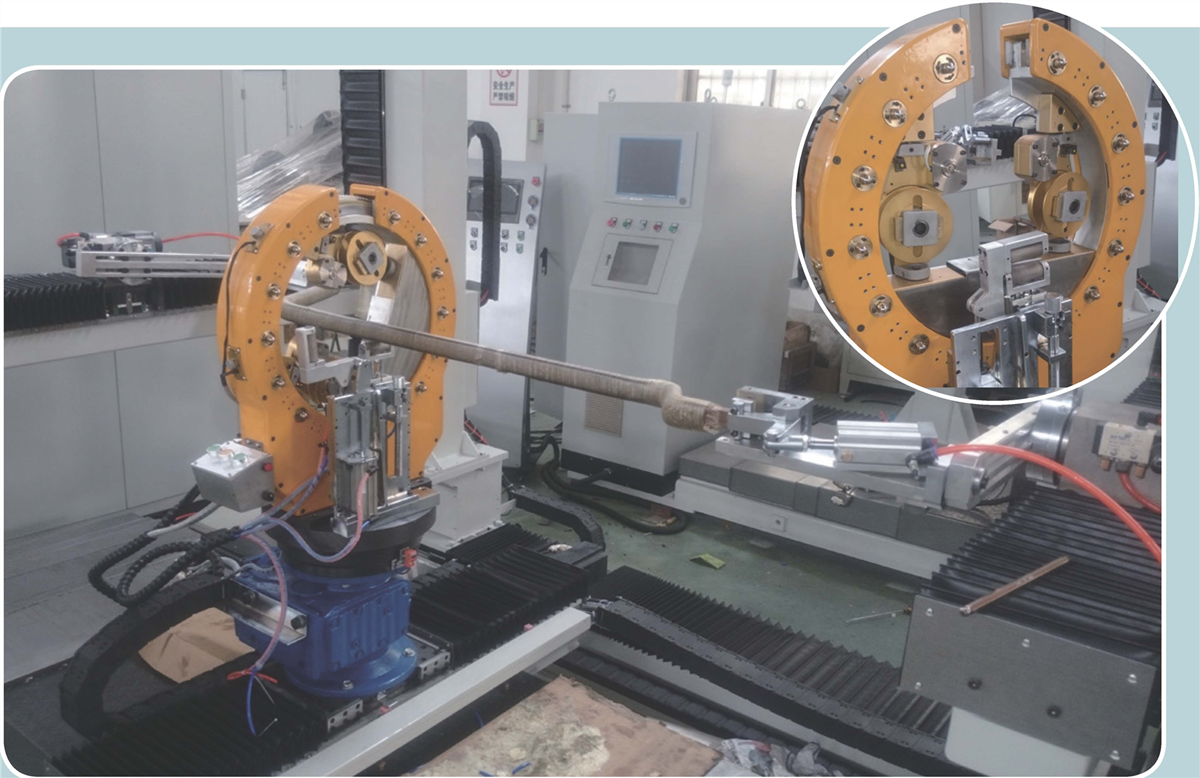

Dual conversion CNC constant tension taping machine

Line: 400~2200mm, opening: 170~1100mm

Double-taping, taping head and walking box each has a variable frequency motor for 15mm, 20mm, 25mm tape.

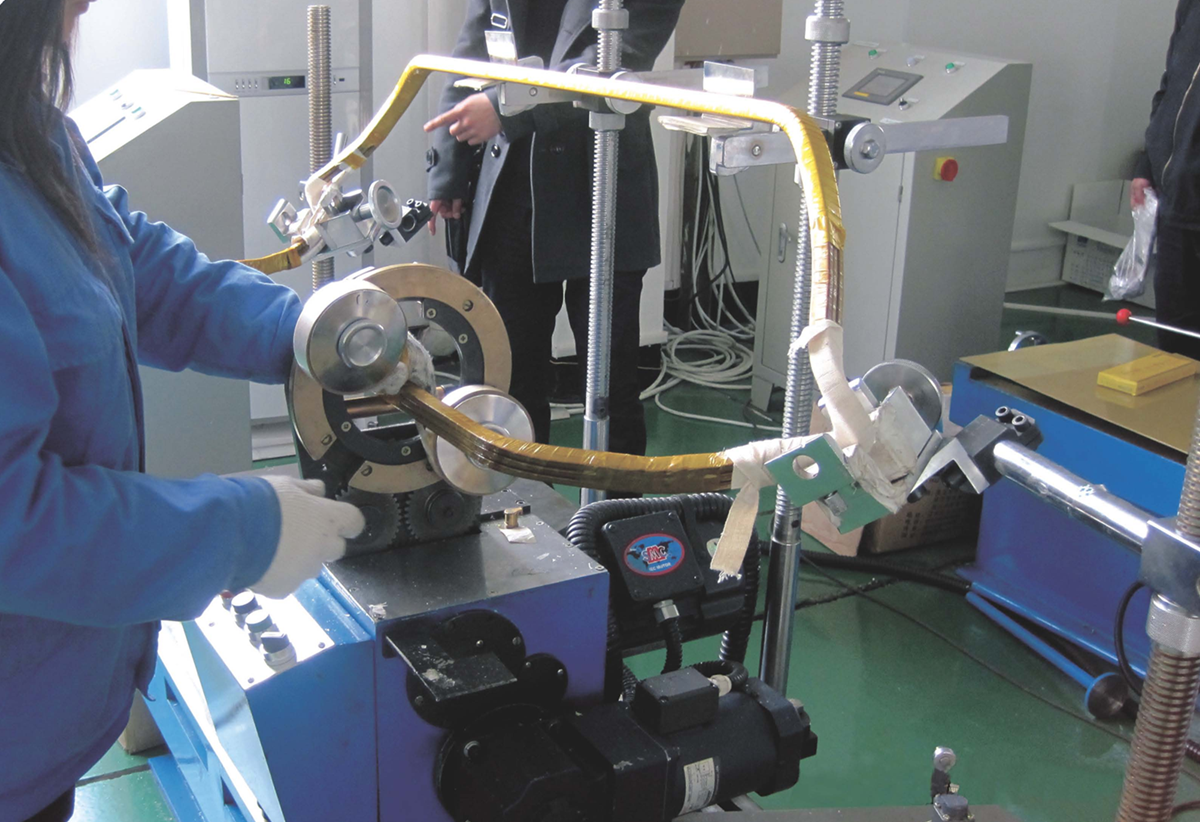

Fusiform coil leading head taping machine

The lead taping will not shake with good taping effect. The multilayer back and forth taping of the mica tape can be realized.

The taping head has the corresponding supporting mechanism to eliminate the lead shaking during the lead taping process. The tension of the taping head's tension wheel is stable to ensure the stability of the tension during the taping process.

The taping length of the lead: 100~700mm;

Line section: 1.33~2.98×6.0~9.3; One or up to six flat mica threads parallel winding coil;